Secondary processing (quilting, transfer printing, etc.)

second-process

At Sankei, we refer to plain items as “primary processing” and to items further processed by quilting, printing, or the like as “secondary processing.” Among secondary processing, the quilting process is one of our particular strong points.

Selection of quilting process

The quilting process can give rise to thousands or tens of thousands of products, depending on the combination of “fabric (raw materials)”, “fiberfill,” and “quilt patterns.” We undertake high added value quilting processes to meet our customers requirements at our quilting factories in Japan and overseas.

Original quilting

-

Fabric

Select by use

We can carry out raw material processing for outers such as wool, denim, and boa from standard raw materials such as basic lining materials for liners and high density raw materials.

(We undertake processing of supplied fabric as well as fabric we have in inventory.) -

Padding

Select by texture

This comes in many varieties that differ in terms of weight, sense of volume, and elasticity.

Select by function

Recent years have seen an increase in fiberfill with functionality such as heat emitting fiberfill and temperature regulating fiberfill.

Select by production site

You can select by production site either product produced in Japan or product produced overseas. -

Pattern

Select from more than 3,000 existing stock patterns

A great variety of patterns are available including standard patterns such as diamonds, stripes and waves, geometric patterns, and boxes.

Create an original pattern

We can create a new pattern based on your design.

Product line-up

(We have many processes not shown below. For details, please talk to a Sankei sales representative.)

- Liner quilting

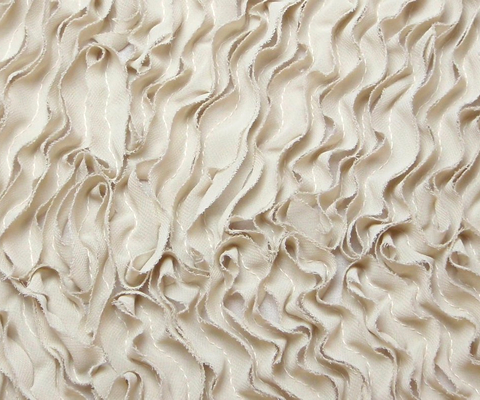

- We process whole cloth with repeated patterns including orthodox patterns like diamonds, stripes, and waves.

- Outer quilting

- We can process outer raw materials, use motif patterns, and perform partial processing.

- Transfer printing

- We can apply transfer prints and use heat and pressure to process overlaid fabric with ink. We can handle even small lots.

- Embroidery

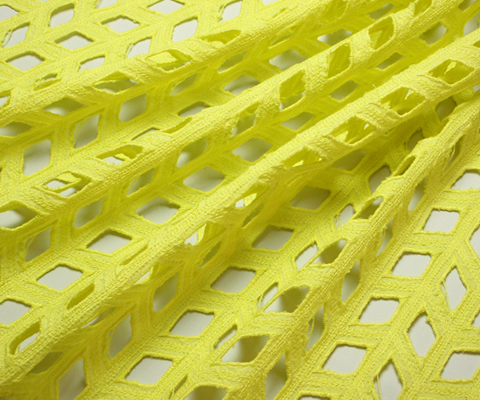

- This is plain fabric to which a needlework process has been applied using an embroidery lace machine. It is also called needlework lace.

- Pleating

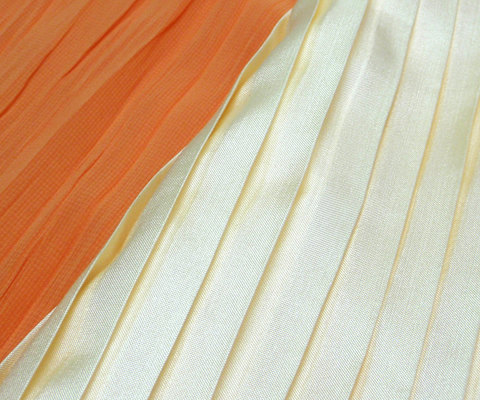

- This is a fabric process involving the use of heat to set folds in fabric to apply a pleated look. It is a process ideally suited to the thermal plasticity of polyester.

- Lamination/bonding

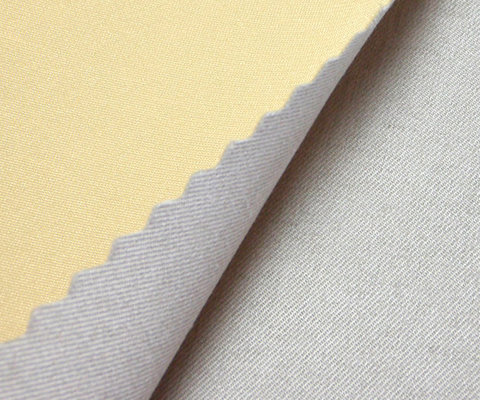

- This process involves the sandwiching of fabric or cotton in a polyurethane film or the spray on and adhesion of urethane resin (adhesive).

- Pinsonic

- This process involves the application of ultrasonic vibrations to fabric held between form rollers to create bonds in the part processed, imparting a pattern.

- Cord needlework

- This is a type of needlework process involving the use of cord or tape on a fabric to impart a pattern.